Industrial operations professionals are facing unprecedented pressure to maintain impeccable quality, reduce downtime, and ensure production lines keep running smoothly. But what if you could enhance your inspection process with cutting-edge computer vision without the hassle of endless data collection for model training? That’s precisely what Aicadium’s proprietary visual inspection technologies are designed to achieve. This post covers two exciting new zero-shot object detection technologies revolutionising industrial inspection processes.

Template-based, zero-shot object detection: Quick quality control, no training necessary

Imagine having a tool that allows you to start inspecting products the moment you upload a reference image—no lengthy setup or complex machine learning. That’s the capability of Aicadium’s pioneering solution. This technology uses your own “golden samples”—images representing what an ideal product or component should look like—as its reference. You provide one or more reference images, and the system gets to work, scanning for matching objects and scoring their similarity in real time.

What’s in it for you?

- Lightning-fast deployment: Say goodbye to lengthy data science marathons. Upload your reference images and start inspecting straightaway.

- Consistent, reliable quality: Each product is checked against your golden standard, helping you catch deviations before they escalate into costly problems.

- Pinpoint precision: Particularly in controlled settings, this solution excels at identifying even small visual discrepancies—ideal for assembly checks, defect detection, and cosmetic inspections.

- Flexibility for your line: Whether you have one template or several, the system adapts effortlessly—no retraining required, just tangible results.

Where does it shine?

- Assembly verification: Ensure every product aligns with your reference, catching assembly errors before they leave the production line.

- Component presence: Confirm that every part is present and properly oriented every time.

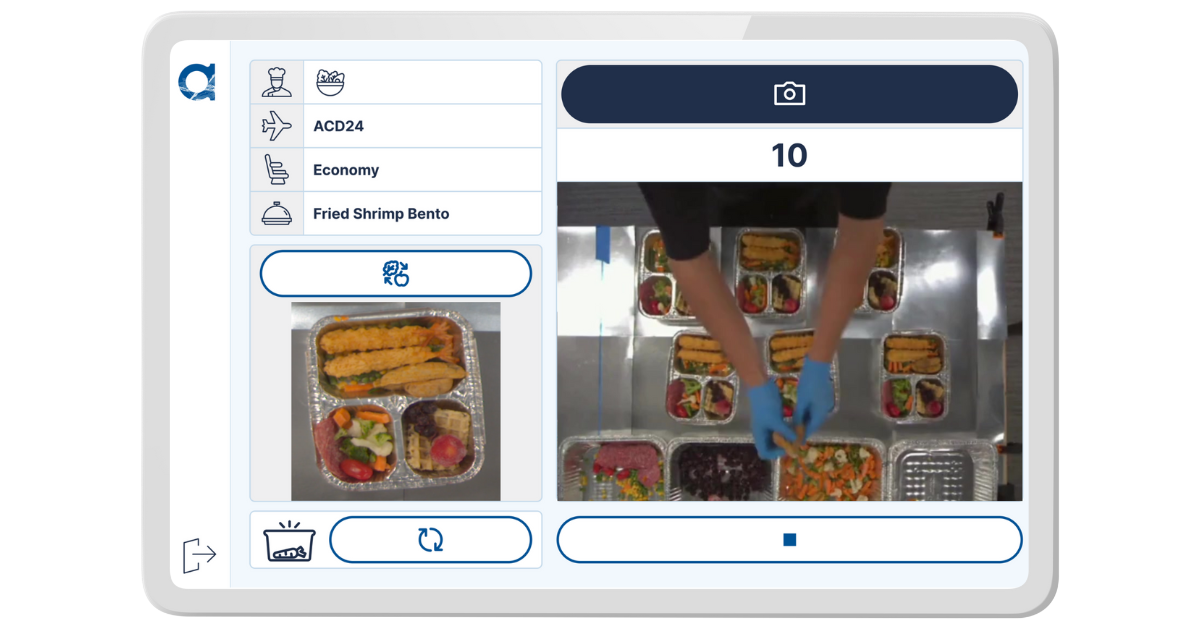

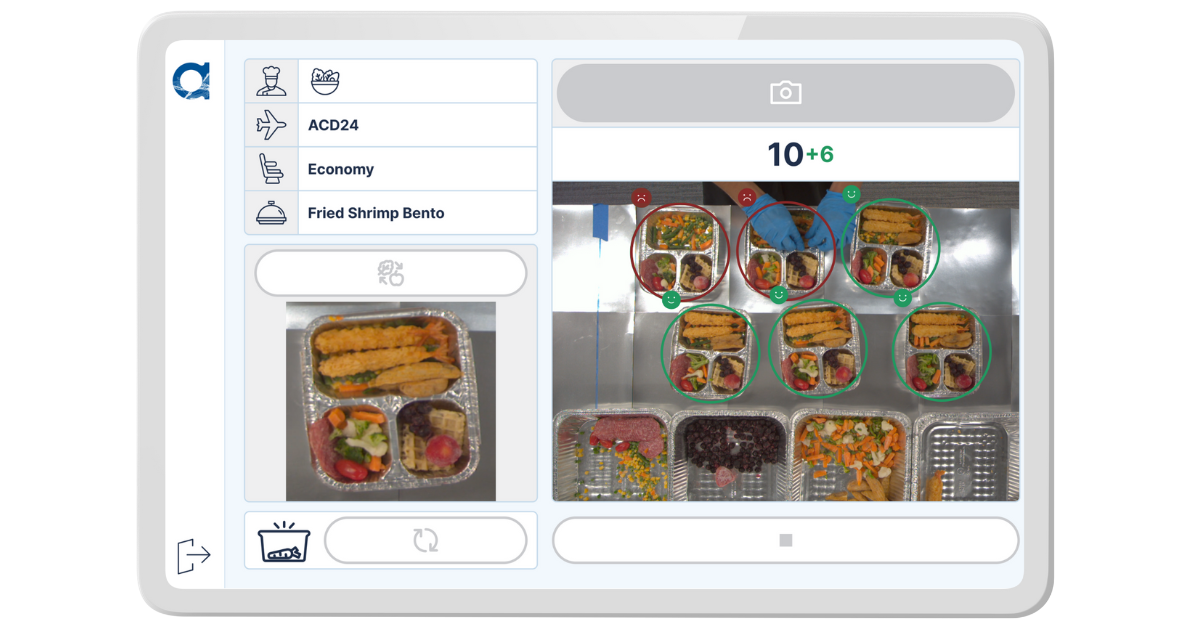

In this example, a “golden” image (left) is captured at the beginning of the meal assembly to compare with all the subsequent dishes assembled. The dishes are then compared to the golden image.

A matching score is applied, and correct and incorrect dishes are marked with easy-to-read green and red circles.

One thing to remember: This technology can quickly move from analysing one product to the next by changing the golden image. However, once you have decided on your golden image for any one product, this tool is geared for consistency. If a product varies significantly in appearance, size, or orientation, it might not be the best fit. But for most manufacturing lines focused on uniformity of a given product, it’s a game changer.

Pixel-level image matching: Your watchful eye for missing parts and alignment

Now, let’s explore Aicadium’s second proprietary innovation—a solution that elevates image matching to an entirely new level. Rather than simply identifying objects, this technology establishes pixel-by-pixel correspondence between two images. Effectively, it’s like having an eagle-eyed inspector who can spot even the most minor variations between a reference photo and a live shot from your line.

Why does this matter?

- Blazing speed and accuracy: With a streamlined model, expect quick, memory-efficient results—perfect for real-time inspection.

- Granular detail: By matching individual pixels, the system can detect missing components or subtle misalignments that a human inspector might overlook.

- Easy integration: All it needs are two images—no complicated setup. Just drop it into your inspection workflow and start gaining insights.

Best use cases

- Component verification: Instantly detect missing or misaligned parts by comparing reference and live images.

- Change detection: Identify what has changed between two snapshots, which is ideal for maintenance or safety checks.

- Image alignment: Accurately align images for documentation or further analysis.

One thing to note: This approach works best when there is enough visual texture in the images. So, blank or featureless surfaces can be challenging. However, for most industrial contexts, it’s spot on.

Which solution fits your operations?

|

Feature/Capability |

Template-Based Detection (Aicadium) |

Pixel-Level Image Matching (Aicadium) |

|

Primary Function |

Object detection & similarity |

Pixel-level correspondence |

|

Training/Data Needs |

Zero-shot; no training |

No sample collection |

|

Sensitivity to Scale/Rotation |

High |

Low |

|

Best Use Cases |

Quality control, defect detection |

Component verification, alignment |

|

Customisation |

Proprietary, customisable |

Proprietary, customisable |

|

Output |

Each object’s location marked with a circle and a similarity score |

Component-level best match location of extra or missing parts marked by a quadrangle and matching score |

Why Aicadium’s approach stands out

Aicadium’s proprietary technologies aren’t just another set of inspection tools. In effect, they represent a significant leap forward for operations professionals seeking fast deployment, reliability, and actionable insights without the typical technical obstacles. In other words, integrating instant, template-based detection with pixel-level matching can address everything from assembly verification to change detection.

Ready to wave goodbye to the headaches of manual inspection? If so, these solutions can focus your team on what really matters: maintaining the efficiency of your production line, delivering top-notch quality, and keeping your customers satisfied. That’s the Aicadium advantage—industrial inspection reimagined for the future.